SOTA SCIENCE

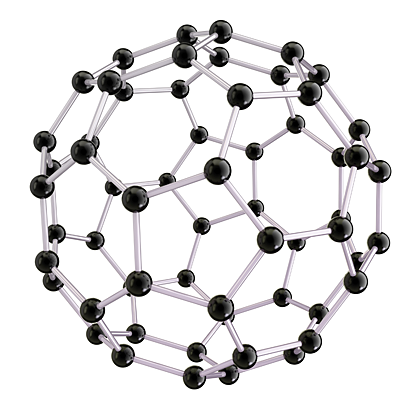

SOTA’s hyper dense HYBRID nanotech coatings are not simply mixed blends of inorganic and organic components. Our unique process reorganizes the organic polymer chains and chemically bonds them within the inorganic lattice structure. A completely integrated lattice matrix results and retains the best properties of each while eliminating virtually all of the less desirable properties of the components when taken individually.

Most conventional industrial coatings are based on organic polymers…extremely large molecules. This backbone provides the coating its capacity to adhere to the substrate, most of its chemical resistance, hardness and flexibility.

Coatings using organic polymers, for the most part, are susceptible to damage and degradation by continued exposure to sunlight. Degradation occurs because radiation in the ultraviolet and blue end of the visible spectrum contains sufficient energy to break chemical bonds within the polymer. Energetic solar radiation can create what are known as 'free radicals' - atoms, molecules, or ions that have unpaired valence electrons or an open electron shell. These 'dangling' electrons make free radicals highly reactive towards other substances, notably the large organic polymer molecules. Free radicals literally tear large organic molecules apart and change their properties in undesirable ways.

As radiation induced degradation occurs, the ability of a conventional coating to provide chemical and corrosion protection also degrades, and this degradation can include whitening of the coating or other compromising events.

To compensate for this common property of polymers, conventional polymer coatings will often contain a small percentage of inorganic material, typically a metallic oxide, to protect against this degradation by radiation. In effect a “sunscreen”.

|